Author: Dayta

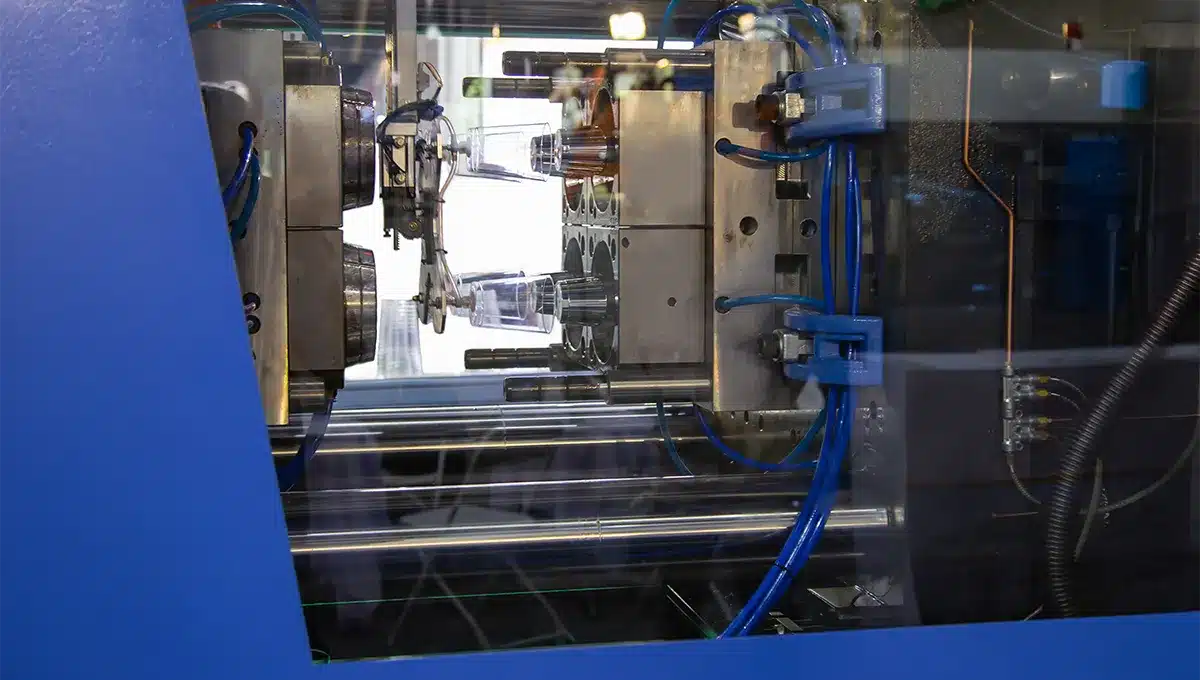

Solving Complexity with the Aerospace Injection Mold Process

Aerospace components are challenging to produce – they must be lightweight and meet strict tolerances, and their complex geometries often push the limits of traditional manufacturing. The risk of failure increases as the designs get more intricate. Structural integrity becomes harder to preserve. Dimensional accuracy can suffer. And scaling production without compromising performance can be tough.

In these cases, the aerospace injection mold process gives you an edge. The method offers the precision, consistency, and attention to detail that modern aerospace design requires.

In this article, you’ll learn how the process supports scalable, high-accuracy manufacturing for aerospace components. By the end, you’ll see why it’s a smart solution for engineering teams looking to move fast without sacrificing quality.

The Challenge of Complexity in Aerospace Components

Every component used in aerospace applications must be as light as possible, structurally sound, and often geometrically intricate to fit within tight spatial constraints. As a designer or engineer, you’re expected to achieve all of this without sacrificing performance.

Unfortunately, manufacturing challenges increase with the complexity of design. Without the right processes, material performance can vary under thermal and mechanical stress. And it is nearly impossible to avoid inconsistencies or defects when scaling to the level of mass production.

What you need is a process that meets these demands head-on. One that delivers repeatable precision, accommodates advanced geometries, and efficiently scales high-volume production of small-to-medium components without compromising on tight tolerances. That’s where the aerospace injection mold process comes in.

Why the Aerospace Injection Mold Process is Ideal

The aerospace injection mold process is built for precision. Compared to many other high-volume methods, this method provides exceptional control over dimensions, material use, and repeatability—particularly once the mold is perfected. Most importantly, it can maintain all of this while producing at a large scale.

Aerospace injection mold has three key benefits:

- Material Versatility. Choose from high-performance, aerospace-grade thermoplastics that meet flame retardancy, mechanical, and chemical resistance standards all while reducing weight and size.

- Dimensional Accuracy. The mold defines the part. Once the mold is perfected, this ensures each component meets precise dimensional requirements within tight tolerances. This kind of accuracy is critical when every thousandth of an inch matters.

- Repeatability. Aerospace injection molds produce identical parts, making it ideal for manufacturing complex aerospace parts in high volume without quality variations.

What Makes TenX Different

Our engineering-first approach is built to help you solve complex challenges from the start. Our in-house team brings deep experience in aerospace applications, and we work with our clients to optimize parts before they hit production.

With advanced injection molding technologies and a library of high-performance polymers, we’re equipped to meet the unique demands of aerospace manufacturing. Whether you’re working with weight-sensitive materials, have exact specifications, or must redesign to meet specific regulatory standards, we’ve got the expertise and tools to deliver.

Partner with TenX for Your Next Project!

Aerospace injection molding delivers what few others can: precision, repeatability, and efficiency at scale. It’s the key to producing complex components without compromising on tolerance or performance.

At TenX, we’ve built our aerospace injection mold process around the needs of engineers in highly technical industries, and we’re here to bring your most complex parts to life.

If you’re looking for a partner who understands your challenges and delivers real solutions, let’s talk. Discover our aerospace injection mold process today.

Contact Us

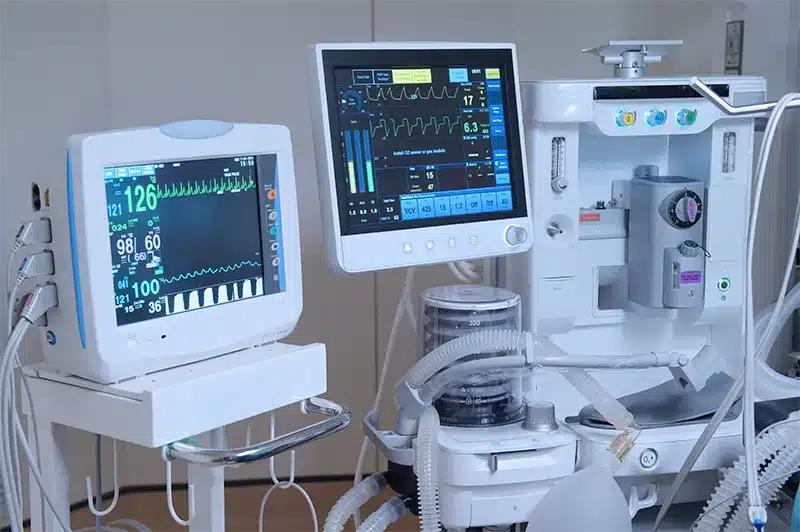

Applications for Injection Molding Medical Device Components

Scaling production of high-performance medical components is no small task when precision, compliance, and repeatability can’t be compromised. In such a strictly regulated industry, the manufacturing process you choose will make all the difference.

In this article, you’ll learn why injection molding medical device components is the ideal method for your industry. We’ll also cover the specific applications where this process excels exceptionally and explain why TenX is your go-to partner.

What Makes Injection Molding Ideal for Medical Components?

Leading medical manufacturers trust injection molding for their most critical medical components. The process delivers tight tolerances, scalable production, and flawless consistency.

Injection molding medical components involves using thermoplastics and high-performance polymers suitable for use in FDA-regulated and ISO-certified environments. These materials provide the strength, biocompatibility, and chemical resistance required for demanding medical applications.

You can also produce high volumes of complex parts at lower per-unit costs while maintaining identical repeatability.

Key Applications of Injection Molding in Medical Devices

- Precision Diagnostic Components

Instrument housings, cartridge components, and enclosures for point-of-care testing require dimensional accuracy within tight tolerances. For these, you can take advantage of injection molds’ repeatable intricate geometries with minimal variance. - Fluid Management and Delivery Systems

Fluid path components – like IV line components, luer fittings, fluid reservoirs, and check valves – meet specific sealing requirements and maintain biocompatibility under sterilization. You can make these injection molding medical components with chemically resistant polymers such as polycarbonate, polypropylene, and medical-grade TPEs. - Surgical and Interventional Tools

Handles, grips, and instrument covers combine structural rigidity with complex ergonomics and surface finish requirements. You can rely on overmolding capabilities for dual-material integration and feel confident that the parts can be designed to withstand autoclave or gamma sterilization, depending on the selected material. - Drug Delivery Devices

Inhaler housings, syringe plungers, and auto-injector mechanisms demand exacting mechanical function, minimal friction between moving parts, and compliance with regulatory standards. With the right manufacturing process, you can get the design precision needed while maintaining consistency across production runs. - Micro and Miniature Components

Things like microfluidic devices, implants, and wearable tech enclosures have sub-millimeter features with high aspect ratios and sharp definition. You can use micro-molding with specialized tooling, precision cavity design, and advanced polymers to consistently replicate micro-scale geometries in mass production volumes.

When to Use Injection Molding in Medical Manufacturing

Injection molding isn’t right for every project. Start by evaluating three critical factors: part complexity, production volume, and material specifications.

Injection molding is ideal when your design involves intricate geometries, thin walls, or high dimensional tolerances that other processes struggle to maintain. If you’re planning for mid-to-high volume production, the upfront tooling investment often pays for itself quickly through lower per-part costs and shorter cycle times.

Material choice also comes into play. Injection molding supports a wide range of medical-grade thermoplastics and performance polymers, like polypropylene, polycarbonate (PC), polyether ether ketone (PEEK), and liquid crystal polymer (LCP).

At TenX, we guide you through the entire design for manufacturability (DFM) process. Our engineering team works alongside yours to optimize part design, reduce scrap rates, and ensure long-term production stability.

Why Partner with TenX for Injection Molded Medical Components

Choosing the right manufacturing partner is as critical as the design itself, especially in the highly regulated medical industry. TenX delivers the infrastructure, expertise, and speed you need to scale with confidence.

We offer in-house toolmaking, giving you faster turnaround and tighter control over mold quality. Our process validation services ensure that every part meets dimensional and performance requirements before full-scale production begins.

TenX is built for regulatory readiness and high-precision manufacturing. We’re the partner who understands both time to market and the real-world demands of the medical industry.

Partner With TenX For Injection Molding Medical Components!

The most complex processes demand a partner with proven expertise and regulatory discipline. At TenX, our injection molding medical components will consistently meet stringent quality and performance standards, while meeting the most stringent tolerances and regulations.

You can’t afford to choose the wrong team. Go with TenX and start producing confidently at any scale. Learn more about our injection molding capabilities.

Contact Us

Increase Quality with High-Volume Custom Injection Molding

When manufacturing precision parts, many companies find that traditional production methods often result in quality variations, costly reworks, and general inefficiencies. When producing thousands – or even millions – of parts that require tight tolerances, things become even more challenging.

High-volume custom injection molding offers a reliable solution. This process is designed to deliver consistent, high-precision parts at scale, minimize quality issues, and ensure every piece meets exact specifications.

The Importance of Quality and Precision in Manufacturing

Consistent, high-precision parts are critical for manufacturers because they directly impact the functionality and reliability of your products. Without precise components, even the smallest variation can lead to defects that affect performance and longevity.

When dealing with inconsistent production, high rejection rates, costly delays, and wasted materials become a regular occurrence. These issues significantly impact your bottom line. Poor precision increases production costs, puts your product’s performance and reliability at risk, and can damage your reputation in the industry.

You can solve these problems by switching to high-volume custom injection molding. The process delivers consistent, high-quality parts with tight tolerances every time.

How High-Volume Custom Injection Molding Solves Quality Issues

High-volume custom injection molding achieves tight tolerances and repeatability through the use of advanced molds that maintain uniformity across large production runs. By using high-quality forms, you can ensure that every component is exact, no matter how many units are produced.

Automation also plays a key role in this process. By relying on machines that aren’t prone to human error, each part will be made with the exact same high standards. You’ll get consistent, repeatable results, which directly leads to higher quality and fewer defects.

Customization Capabilities for Enhanced Performance

With high-volume custom injection molding capabilities, you can tailor designs to your specific industry needs, whether you work with medical tools, aerospace components, or electronics. You have the flexibility to choose the best material for each application and execute complex geometries without sacrificing accuracy.

This means you can produce intricate designs that maintain high precision and function as intended in even the most challenging environments.

Benefits of High-Volume Production for Consistency

High-volume production brings economies of scale. As production volume increases, the cost per part decreases while your ability to maintain consistent, high-quality output remains steady.

In contrast, low-volume production tends to involve more frequent changes in tooling, manual setup, and less automated control, leading to increased variability in each batch. These fluctuations can introduce defects, such as dimensional inaccuracies or surface imperfections.

Take the consumer electronics industry, for instance. Plastic housings for mobile devices must be lightweight, durable, and visually appealing. By using high-volume custom injection molding, manufacturers can achieve the same color, texture, and dimensions across millions of parts.

Choose TenX for High-Volume Custom Injection Molding

Manufacturers looking for scalable, high-performance production should consider high-volume custom injection molding. The efficiency of automation reduces waste and minimizes the need for costly reworks, while economies of scale bring down the cost per part.

Investing in high-precision molds also guarantees repeatability across thousands or even millions of units, making it a reliable and cost-effective option for large-scale manufacturing. Take your production to the next level with TenX. Learn more about our high-volume custom injection molding capabilities.

Contact Us

Choosing Between Extrusion Molding vs. Injection Molding For Medical Device Manufacturing

When it comes to manufacturing medical components at scale, choosing the right process is more than a technical decision—it’s a strategic one. The decision between extrusion and injection molding depends on factors like dimensional tolerances, material behavior, production throughput, and regulatory compliance.

In this blog by TenX Manufacturing, you’ll learn how each process compares—and why injection molding often provides a clear advantage for high-volume medical programs.

Extrusion Molding Vs Injection Molding: Considerations for High-Volume Production

Extrusion

While extrusion remains a go-to method for producing tubing and other linear medical components, scaling this process for high-volume programs introduces specific challenges that require early consideration. Maintaining dimensional consistency across millions of feet of product demands robust in-line inspection systems and real-time process control to prevent downstream quality issues.

Additionally, secondary operations—such as hole punching, tip forming, bonding, and coiling—must be tightly integrated into the production flow to minimize labor and handling. For devices requiring multi-durometer or multi-lumen designs, tooling precision and material flow control become critical for performance and compliance. Finally, if components are part of a sterile or Class II/III assembly, manufacturers must ensure traceability, cleanroom compatibility, and validated post-processing—all of which can impact lead times and cost structure in high-throughput environments.

Injection

Injection molding is often the preferred method for producing complex, tight-tolerance medical components at scale—but unlocking its full value in high-volume programs requires careful alignment between part design, tooling strategy, and regulatory requirements. Tooling must be engineered not just for repeatability but for longevity under sustained cycles, especially when dealing with high-performance resins like PEEK or PSU. Design flexibility allows for complex geometries, overmolding, and integration of features that reduce downstream assembly steps—critical advantages when scaling.

However, to justify the upfront tooling investment, volumes must support amortization, and part designs should be locked in prior to steel. For regulated devices, molds must also support validated processes (IQ/OQ/PQ), cavity-to-cavity consistency, and complete lot traceability. Cleanroom molding, material handling protocols, and in-mold monitoring systems all contribute to ensuring quality and compliance without compromising throughput.

Why Injection Solutions Deliver Greater Value at Scale

For high-volume production, injection molding offers key advantages that extend beyond part complexity. Its ability to consistently replicate intricate geometries across millions of cycles is critical for maintaining functional performance and regulatory compliance—especially for components with tight tolerances or precision mating features.

Material efficiency is another advantage, with minimal waste due to closed-loop systems and efficient shot control—particularly important when working with costly medical-grade polymers. Injection molding’s versatility allows for multi-material integration, part consolidation, and built-in assembly features, all of which reduce downstream labor and potential points of failure.

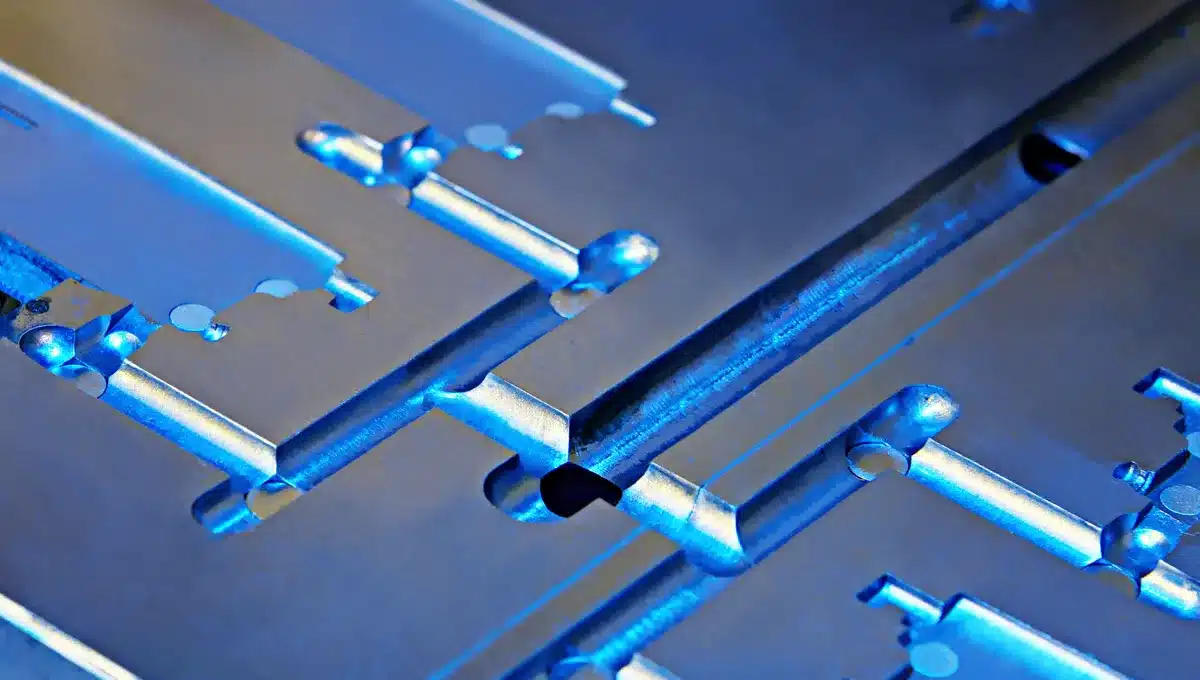

While upfront tooling costs are higher, they’re quickly offset in high-volume runs, especially when leveraging high-cavitation or family molds that significantly reduce per-unit cost without sacrificing throughput or quality.

Why TenX Stands Out in Injection Molding

At TenX Manufacturing, we specialize in high-volume production, delivering unparalleled quality and precision for the medical industry. Our advanced processes and commitment to excellence ensure that your project benefits from exceptional precision, material efficiency, and scalability.

Take the next step with TenX Manufacturing. Contact us today to discuss your project needs and discover how our injection molding services can help you achieve your goals.

Take the next step with TenX Manufacturing

Contact us today to discuss your project needs and discover how our injection molding services can help you achieve your goals.

Contact Us

Full-Service Injection Molding Solutions Partner at TenX Manufacturing

When it comes to injection molding solutions, finding a reliable partner who can handle every aspect of the process is crucial to your project’s success. At TenX Manufacturing, we stand out in the industry by offering a comprehensive suite of injection molding solutions—DFM (Design for Manufacturing), injection mold tooling, molded parts, and assembly—all under one roof. This unique capability allows us to deliver exceptional results efficiently and effectively.

Comprehensive Injection Molding Solutions

At TenX Manufacturing, we understand that the success of any injection molding project starts with meticulous planning and design. Our DFM services ensure that your designs are optimized for manufacturability, reducing production costs and time. We work closely with you to assess every aspect of your project, identifying potential challenges and opportunities to enhance performance.

Here’s how we streamline the injection molding process:

- DFM (Design for Manufacturing): Our expert team collaborates with you from the very beginning to refine your designs, ensuring they are feasible for production. By identifying potential issues early on, we can prevent costly revisions later in the process.

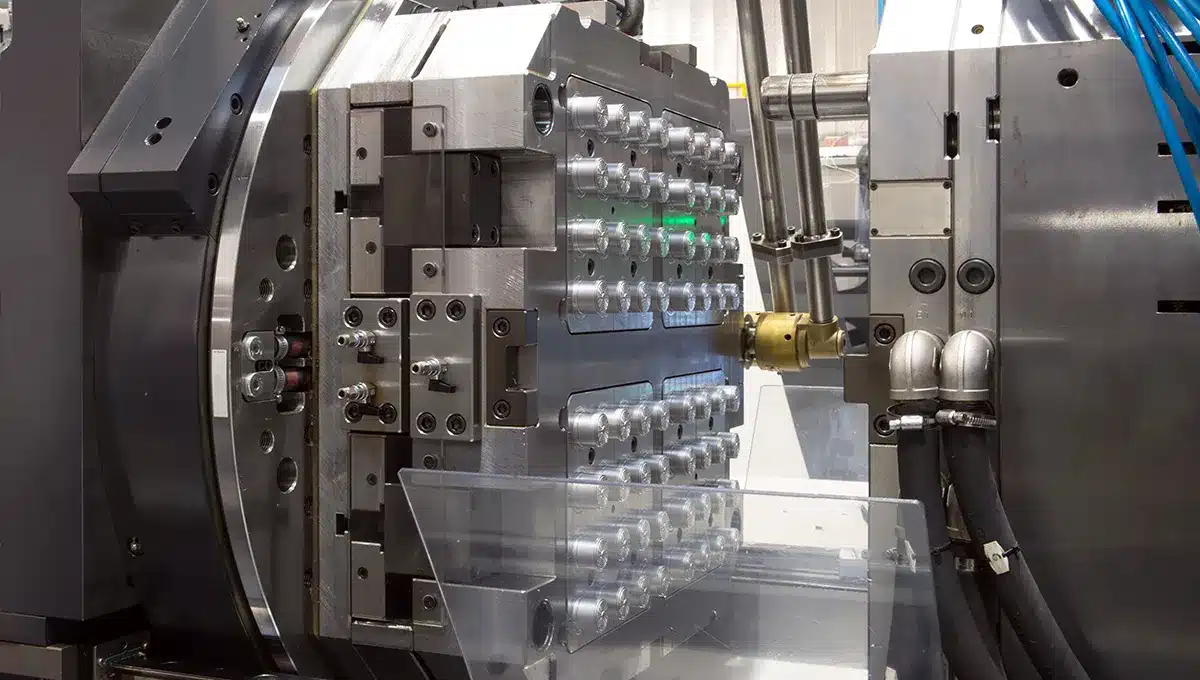

- Injection Mold Tooling: With our state-of-the-art facility and advanced equipment, we create high-quality molds that meet your specific requirements. Our in-house tooling capabilities mean faster turnaround times and improved quality control, as we can address any adjustments immediately.

- Molded Parts Production: Whether you need prototypes, bridge solutions, or full-scale production, we have the expertise and technology to deliver. Our experienced team ensures that every molded part meets rigorous quality standards, providing you with confidence in your final product.

- Assembly Services: To further simplify your manufacturing process, we offer comprehensive assembly services. Our team can handle the assembly of components, allowing you to receive fully finished products ready for market. This streamlined approach reduces the need for multiple suppliers and enhances communication throughout the project.

Flexibility to Meet Your Needs

At TenX Manufacturing, we recognize that each project is unique. That’s why we cater to a variety of production volumes—be it prototype, bridge, or full production runs. Our agility allows us to adapt to your specific requirements, ensuring that we deliver solutions tailored to your needs.

Why Choose TenX Manufacturing?

Choosing TenX Manufacturing means partnering with a company committed to excellence. Here are a few reasons why we stand out in the injection molding landscape:

- All-in-One Solution: With DFM, tooling, molded parts, and assembly services available in-house, we provide a seamless experience from concept to completion.

- Quality Assurance: Our ISO 9001:2015 certification underscores our commitment to quality, ensuring that every product meets stringent international standards.

- On-Time Delivery: Our optimized processes enable us to deliver your orders promptly, keeping your projects on schedule.

- Customer-Centric Approach: We prioritize clear communication and collaboration, ensuring your needs and feedback are always at the forefront of our operations.

Let’s Bring Your Vision to Life

At TenX Manufacturing, we are passionate about turning your ideas into reality through our innovative injection molding solutions. Our experienced team is ready to work with you, providing the expertise and support you need to achieve your manufacturing goals.

Contact us today to discuss how we can elevate your projects with our comprehensive injection molding services. Together, we can create high-quality products that stand out in the marketplace and drive your success.

Request a Quote

TenX: The Best Manufacturing Company to Elevate Your Production

In the world of manufacturing, the best manufacturing company will become your partner who not only understands your needs but also consistently delivers top-quality solutions. Finding such a company can be a challenge. At TenX Manufacturing, we pride ourselves on our rich heritage and our unwavering commitment to excellence. With over four decades of experience, we have transformed from a small garage operation into a leading manufacturer with an impressive 80,000-square-foot facility equipped with cutting-edge technology.

A Legacy of Excellence

Founded in 1980 as Schmit Prototypes, our journey began with a focus on cast urethane parts and visual models. Through dedication and innovation, we quickly earned a reputation as the best manufacturing company known for our high level of quality in these specialized services. As our clients’ needs evolved, so did our capabilities. Today, we offer an extensive range of manufacturing solutions, including:

- Injection Molding (tooling, molded parts, assembly)

- CNC Machining

- Cast Urethane & Silicone Parts

- 3D Printing

This evolution has enabled us to not only provide low-volume and prototype work but also to transition seamlessly into full-scale production. Our rebranding to TenX Manufacturing reflects this commitment to going above and beyond for our customers.

What Does “TenX” Mean?

The name “TenX” encapsulates our mission and values:

- Ten: Representing our 10+ in-house capabilities, we strive to offer diverse manufacturing solutions tailored to your unique needs.

- X: Symbolizing our versatility, we provide both prototype and production volumes, ensuring that whatever your project demands, we are equipped to deliver.

Our customer-centric approach, combined with our state-of-the-art technology, empowers your business with manufacturing solutions designed to propel your success to new heights.

Commitment to Quality: ISO 9001:2015 Certified

Quality is at the heart of everything we do. Our ISO 9001:2015 certification is a testament to our dedication to maintaining the highest standards in manufacturing. This internationally recognized certification ensures that our processes consistently meet or exceed customer requirements and regulatory standards.

How does this benefit you?

- Enhanced Product Quality: Our ISO certification assures you that the products you receive will meet international quality standards, giving you confidence in your investment.

- Improved Customer Service: With a robust quality management system in place, we prioritize clear communication and prompt responses to your inquiries and concerns.

- On-time Delivery: Our streamlined production schedules and logistics optimization mean that you can count on us for timely deliveries, keeping your projects on track.

- Continual Improvement: We are committed to refining our processes based on your feedback, ensuring that we always strive for excellence in our products and services.

Work With The Best Manufacturing Company: Partner With TenX

As you consider your manufacturing needs, remember that TenX Manufacturing is more than just a supplier; we are your dedicated partner in innovation and quality. Our expansive capabilities, commitment to excellence, and customer-first approach make us the ideal choice for businesses looking to elevate their production experience.

Let us empower your success—contact us today to discuss how TenX Manufacturing can help you achieve your goals with precision and efficiency. Together, we can build a brighter future for your business.

Request a Quote

Ultimate Benefits of Plastic Injection Molding

Plastic injection molding stands out as a cornerstone of modern manufacturing. Its ability to produce complex, high-quality components quickly and at scale makes it indispensable for keeping up with the growing demand for efficient, versatile, and cost-effective manufacturing solutions.

This blog will guide you through the key benefits of plastic injection molding to help you see why it’s a preferred choice in sectors like medical tools, agriculture, aerospace, transportation, and electronics. By the end, you’ll clearly understand how this process can enhance your next manufacturing project.

What is Plastic Injection Molding?

Plastic injection molding is a manufacturing process where plastic material is melted and injected into a precisely crafted mold. Once the molten plastic fills the mold, it cools, solidifies, and takes on the desired shape with high precision.

Plastic injection molding is versatile enough to be used across various industries, and it can produce everything from intricate components to large, functional parts.

7 Benefits of Plastic Injection Molding

The many benefits of plastic injection molding make it a preferred manufacturing process for companies looking to increase operational efficiency and product quality:

1) Cost-Effectiveness

Plastic injection molding significantly reduces production costs, especially for large-volume orders. Additionally, the process results in extremely precise mold designs, reducing raw material waste. While the initial investment into this new process may seem high, the long-term savings in production efficiency and reduced material usage quickly offset the cost.

2) High Precision and Consistency

Another key benefit of plastic injection molding is its ability to deliver precision and consistency for complex designs. Once you create the mold, each product is virtually identical to the last. This level of precision and consistency is essential for highly regulated industries like aerospace, healthcare, and automotive.

3) Material Versatility

Plastic injection molding works with a wide range of plastics, including high-strength polymers and heat- or chemical-resistant options. The process also supports co-injection molding, in which you can combine multiple materials in a single component.

4) Design Flexibility

With plastic injection molding, you can create intricate shapes and fine details that might be challenging or impossible with other manufacturing methods. This flexibility opens the door for innovative designs so you can push boundaries and deliver cutting-edge solutions to your market.

5) Fast Production Cycle

components without compromising quality. Whether you need a small batch or a large-scale order, you can stay ahead of deadlines and keep your projects on track.

6) Enhanced Product Durability

When you use plastic injection molding, you can select materials with specific properties, such as resistance to wear, temperature fluctuations, or impact. You can trust that your components will perform under demanding conditions for the long term.

7) Environmental Sustainability

You can support environmental sustainability by incorporating recyclable materials into the plastic injection molding machine. Additionally, the process consumes less energy and creates less waste than traditional manufacturing methods.

Comparing Plastic Injection Molding to Other Methods

There are several benefits of plastic injection molding compared to other manufacturing methods like 3D printing, blow molding, and CNC machining. While 3D printing excels in prototyping, it struggles with high-volume production due to slower speeds and higher costs. Blow molding is practical for hollow parts but lacks the design flexibility and precision of injection molding. Although highly precise, CNC machining is typically slower and more costly for mass production.

Plastic injection molding stands out for its cost efficiency, speed, and scalability. It allows for rapid production of large quantities at a lower cost per unit. Maintaining high precision and consistency across large runs sets injection molding apart from other methods, offering the best balance of performance and economy.

Partner with TenX

Whether you’re working in medical tools, aerospace, or electronics, the benefits of plastic injection molding are clear – cost-effectiveness, high precision, design flexibility, fast production cycles, enhanced durability, and environmental sustainability.

Partner with TenX to make the most of these advantages and ensure your next manufacturing project is a success.

Request a Quote

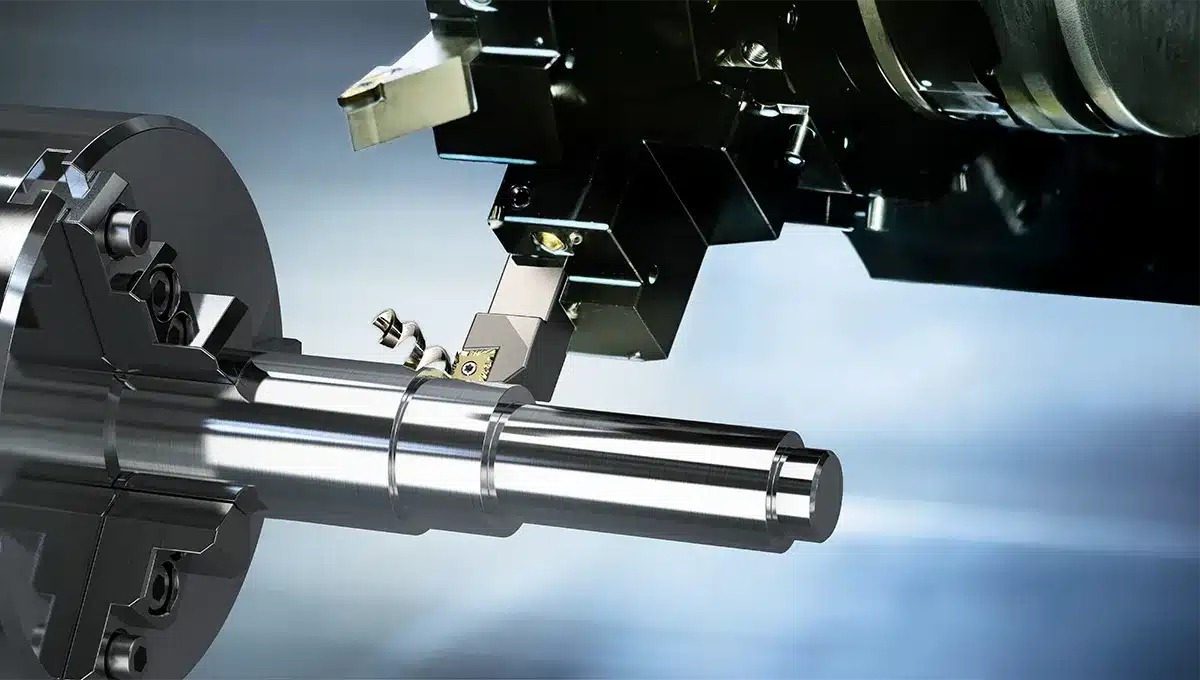

Manufacturing Efficiency With CNC Technology

CNC (Computer Numerical Control) machining is a process where pre-programmed computer software dictates the movement of machinery and tools. This precise technology produces complex parts with incredible accuracy, consistency, and quality.

Automating the mass production of intricate designs with CNC has significantly increased manufacturing efficiency in the modern age. Today, the technology is indispensable for industries ranging from automotive to aerospace.

How CNC Improves Manufacturing Efficiency

Precision and Accuracy

CNC machines are renowned for their exceptional precision. Unlike manual machining, where human error can lead to inconsistencies, CNC machining makes each component to exact specifications. This level of accuracy improves the quality of the final product and minimizes the need for costly rework.

Automation and Consistency

By minimizing human involvement, CNC technology also reduces the potential for mistakes. The technology delivers uniform products and ensures they each meet the same high standards. This reliability enhances product quality and streamlines production, making it easier to achieve consistency across large production runs.

Faster Production Times

CNC machines offer significant speed advantages over traditional manufacturing methods – they can operate continuously, at high speeds, and with minimal downtime. The rapid production capability of CNC is essential in meeting tight deadlines and increasing overall manufacturing efficiency.

Versatility and Flexibility

One of the standout features of CNC machining is its ability to produce complex geometries that are difficult or impossible to replicate with other methods. The machines have versatile reprogramming capabilities, so you can quickly shift between different projects without extensive retooling.

Reduced Labor Costs

CNC automation inherently reduces the need for highly skilled manual labor. Instead of relying on traditional machinists to produce parts, CNC operators and programmers oversee the process. This shift can lead to significant savings when it comes to payroll.

Enhanced Material Utilization

CNC machining is designed to optimize material usage, therefore reducing waste. By precisely controlling the cutting and shaping processes, CNC machines minimize excess and maximize the yield from raw materials.

Integration with CAD/CAM Software

Integrating CNC machines with CAD and CAM software bridges the gap between design and manufacturing. By seamlessly translating complex blueprints into physical components with CNC, you can increase manufacturing efficiency and production flexibility.

Scalability

Unlike processes that require different setups or tools as production volumes increase, CNC machines can meet varying production needs without losing precision or efficiency. This capability makes CNC machining ideal for everything from prototyping to full-scale production, regardless of output count.

Commitment to Manufacturing Efficiency

CNC machining is superior for manufacturing due to its consistent, high-quality results with minimal waste and downtime. At Ten X, we are committed to delivering the highest levels of efficiency and quality in every project we undertake. Our state-of-the-art CNC machines and skilled team of experts allow us to meet the most challenging manufacturing demands with precision and speed. Request a quote for your next project.

Request a Quote

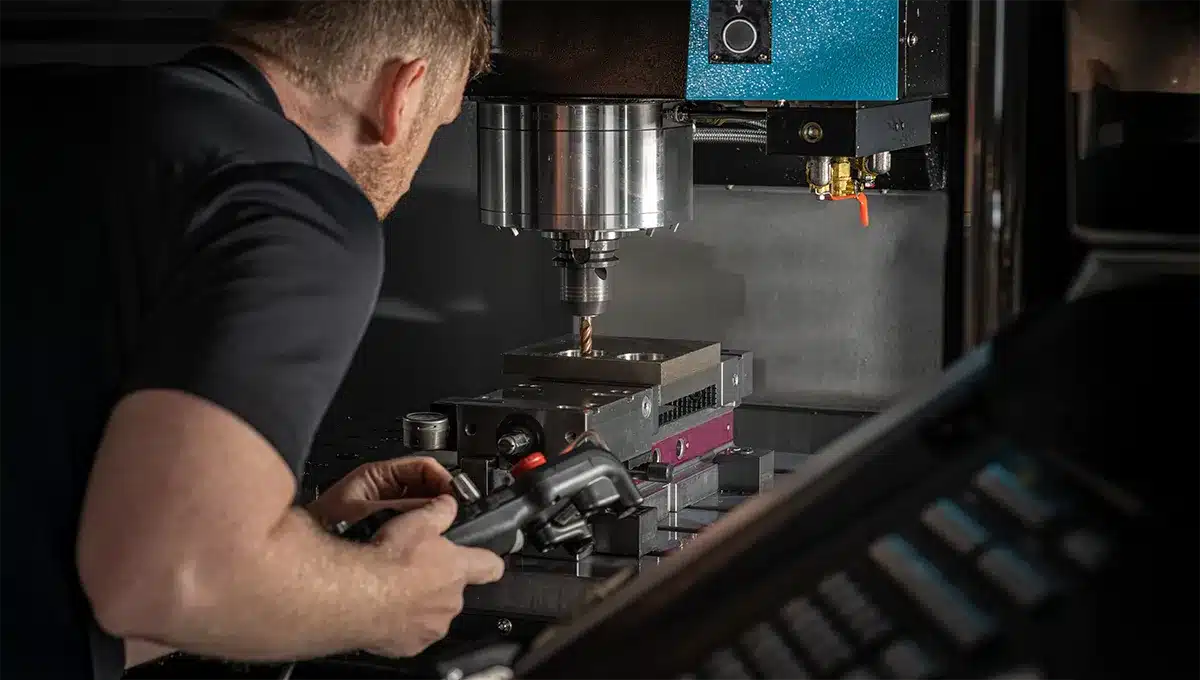

Benefits of Using a CNC Machine for Medical Parts Manufacturing

Precision and reliability are non-negotiable in medical parts manufacturing. As a company that sells medical instruments, you understand the critical need to produce tools that meet exact standards.

Computer numerical control (CNC) machining ensures medical parts are manufactured with the highest quality and precision, eliminating the potential for errors even at large scales. By working with a CNC medical parts manufacturing partner, you can mitigate risks, streamline production, and ultimately deliver superior products that uphold the integrity of your company.

Let’s explore how CNC machining can help you stay ahead in the competitive medical field.

What is CNC?

CNC, or computer numerical control, is a sophisticated manufacturing process that utilizes computerized controls and machinery to automate complex aspects of production. Pre-programmed software and code direct the cutting, drilling, milling, and shaping of materials, resulting in highly accurate and consistent outputs.

CNC machines can handle a wide range of materials, from metals and plastics to composites. They can also produce intricate designs with tight tolerances that would be challenging or impossible to achieve manually. Its versatility makes it a popular choice across many industries, including automotive, aerospace, and medical.

Advantages of using CNC for Medical Parts Manufacturing

CNC technology has become invaluable in medical parts manufacturing, minimizing human intervention and maximizing precision. Here are some advantages:

Unparalleled Accuracy

CNC machining allows for the production of medical parts with extremely tight tolerances, often down to micrometers. This level of precision is crucial for medical components, where even minor deviations can impact the functionality and safety of devices.

Production Consistency

CNC machining can consistently produce identical parts, regardless of the production scale. This repeatability is vital in the medical field, where components must adhere to strict regulatory standards, and any variation can lead to compliance issues or product recalls. CNC machines can replicate the same process multiple times, ensuring that each batch of parts meets the same high standards as the first.

Material Compatibility

CNC machines are compatible with various materials, including metals, plastics, ceramics, and composites. This versatility is essential in the medical industry, where different applications may require specific materials based on biocompatibility, strength, and durability requirements.

Safety & Compliance

The precision and consistency offered by CNC machines ensure that medical parts meet regulatory requirements, reducing the risk of non-compliance and potential liability issues. Additionally, CNC systems can maintain detailed records of production processes, aiding in traceability and quality assurance.

Cost-Effective High-Volume Production

CNC machining minimizes material waste, reduces labor costs due to automation, and lowers the likelihood of defects – all contributing to cost savings. Your company can produce higher-quality components at a lower price, which can be passed on as savings to healthcare providers and patients.

CNC machining offers a comprehensive solution for manufacturing medical parts. With high precision, consistency, and efficiency while accommodating complex designs and various materials, CNC can help you bring reliable and safe medical devices to the market.

Ten X CNC Medical Parts Manufacturing

Ten X is here to help you manufacture medical parts at the highest quality without mistakes. Request a quote when you’re ready to create safe and reliable products with CNC machining.

Request a Quote

Production Success: Design for Manufacturing and Assembly

The intricacies of production often make it difficult for companies to create a design for manufacturing and assembly (DFMA) that balances material selection, supply chain logistics, and product performance. As engineers and procurement professionals know, functionality, cost, and efficiency are critical aspects of bringing a product to market. This is where partnering with an original equipment manufacturer (OEM) can be invaluable.

OEMs have the expertise and resources to refine your design, ensuring it is manufacturable at scale while maintaining quality and performance. By leveraging their experience and specialized knowledge, you can streamline the production process, reduce costs, and mitigate risks.

This article explains what design for manufacturing is, its benefits, and how an OEM can help your company achieve its goals.

What is Design for Manufacturing and Assembly?

DFMA involves optimizing a product concept to reduce the number of parts, simplify assembly steps, and use standard components whenever possible. The goal is to minimize production costs and complexity while maintaining or improving product quality and performance.

By incorporating DFMA principles, you can create more cost-effective, reliable, and efficiently assembled products, ultimately leading to greater customer satisfaction and competitive advantage.

Benefits of Design for Manufacturing and Assembly

Here are some ways DFMA can improve your product development process:

Reduced Costs

OEMs utilize DFMA best practices to simplify the design and minimize the need for complex manufacturing processes. This can benefit your company by reducing material costs, labor expenses, and equipment costs. Expert OEMs achieve this cost reduction without compromising the product’s functionality, leading to a more economically viable product.

Improved Quality

By streamlining the design and focusing on ease of manufacturing and assembly, DFMA reduces the chances of defects and errors during production. Fewer parts mean fewer potential points of failure, and simplified assembly processes can reduce the likelihood of incorrect assembly. Producing a higher-quality product that consistently meets expectations can ultimately enhance your reputation and customer satisfaction, leading to increased business success.

Faster Time to Market

DFMA allows for more efficient manufacturing processes by addressing potential issues early in the design phase. By optimizing the design for easy manufacturing and assembly, you can significantly reduce the time required for production, testing, and adjustments. This accelerated timeline can give your company a competitive edge by allowing it to bring new products to market faster than its competitors.

Enhanced Design Flexibility

By considering manufacturing and assembly constraints from the beginning, OEMs can identify potential issues and adjust your design accordingly. This proactive approach prevents costly redesigns later in the development cycle and enables more seamless integration of new technologies or features.

A More Collaborative Approach

DFMA encourages closer collaboration between your company’s design engineers and your manufacturing partner. By working together from the start, these teams can identify potential manufacturing challenges and find solutions early. This collaboration fosters a more integrated approach to product development, resulting in more manufacturable and assembly-friendly designs.

DFMA provides a comprehensive framework for creating more efficient, cost-effective, and high-quality products. By integrating these principles into the design process, you can achieve significant advantages in all stages of development, production, and retail.

Ten X Design for Manufacturing and Assembly

Are you looking to bring a new product to market or improve your current process with a new manufacturing partner? The design for manufacturing and assembly team at Ten X specializes in injection molded parts, CNC machining, and urethane casting. We are here to help you refine your product’s design and handle all aspects of manufacturing for you.

Request a Quote