Blogs

Full-Service Injection Molding Solutions Partner at TenX Manufacturing

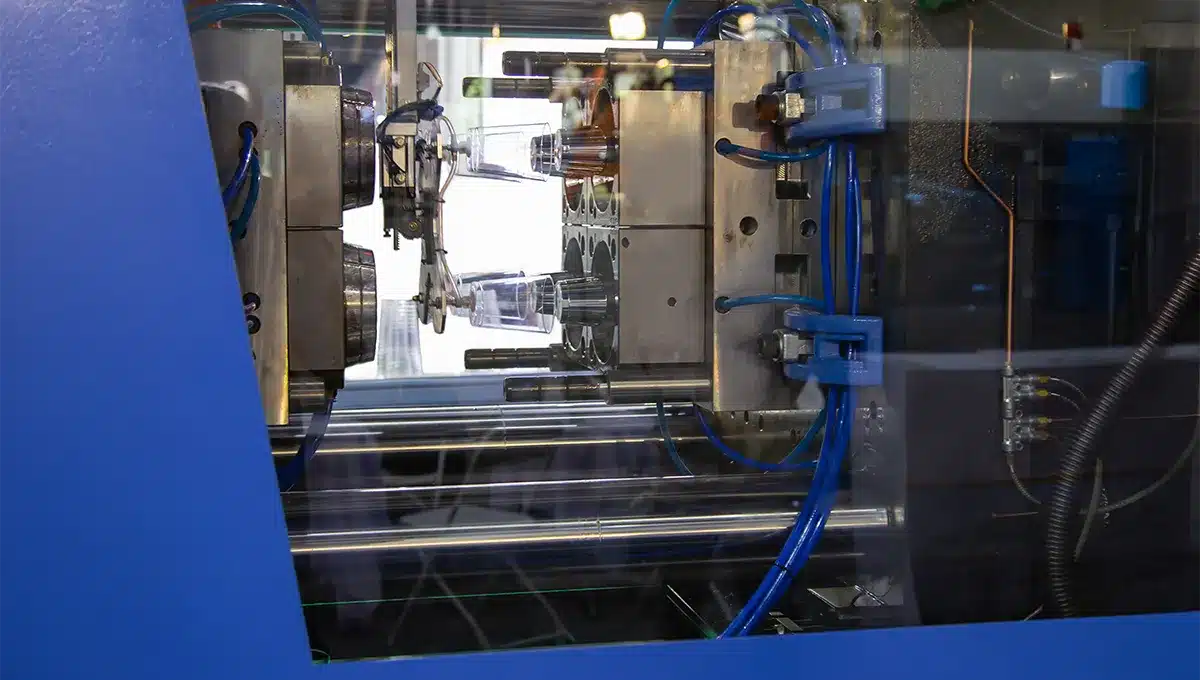

When it comes to injection molding solutions, finding a reliable partner who can handle every aspect of the process is crucial to your project’s success. At TenX Manufacturing, we stand out in the industry by offering a comprehensive suite of injection molding solutions—DFM (Design for Manufacturing), injection mold tooling, molded parts, and assembly—all under one roof. This unique capability allows us to deliver exceptional results efficiently and effectively.

Comprehensive Injection Molding Solutions

At TenX Manufacturing, we understand that the success of any injection molding project starts with meticulous planning and design. Our DFM services ensure that your designs are optimized for manufacturability, reducing production costs and time. We work closely with you to assess every aspect of your project, identifying potential challenges and opportunities to enhance performance.

Here’s how we streamline the injection molding process:

- DFM (Design for Manufacturing): Our expert team collaborates with you from the very beginning to refine your designs, ensuring they are feasible for production. By identifying potential issues early on, we can prevent costly revisions later in the process.

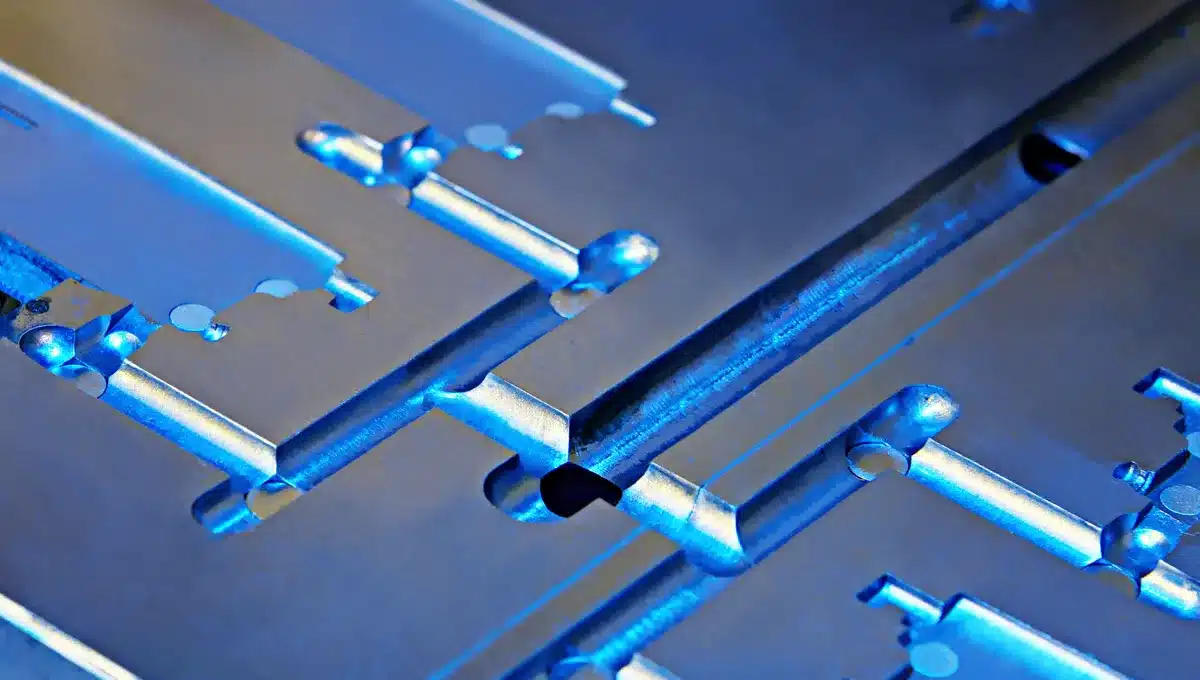

- Injection Mold Tooling: With our state-of-the-art facility and advanced equipment, we create high-quality molds that meet your specific requirements. Our in-house tooling capabilities mean faster turnaround times and improved quality control, as we can address any adjustments immediately.

- Molded Parts Production: Whether you need prototypes, bridge solutions, or full-scale production, we have the expertise and technology to deliver. Our experienced team ensures that every molded part meets rigorous quality standards, providing you with confidence in your final product.

- Assembly Services: To further simplify your manufacturing process, we offer comprehensive assembly services. Our team can handle the assembly of components, allowing you to receive fully finished products ready for market. This streamlined approach reduces the need for multiple suppliers and enhances communication throughout the project.

Flexibility to Meet Your Needs

At TenX Manufacturing, we recognize that each project is unique. That’s why we cater to a variety of production volumes—be it prototype, bridge, or full production runs. Our agility allows us to adapt to your specific requirements, ensuring that we deliver solutions tailored to your needs.

Why Choose TenX Manufacturing?

Choosing TenX Manufacturing means partnering with a company committed to excellence. Here are a few reasons why we stand out in the injection molding landscape:

- All-in-One Solution: With DFM, tooling, molded parts, and assembly services available in-house, we provide a seamless experience from concept to completion.

- Quality Assurance: Our ISO 9001:2015 certification underscores our commitment to quality, ensuring that every product meets stringent international standards.

- On-Time Delivery: Our optimized processes enable us to deliver your orders promptly, keeping your projects on schedule.

- Customer-Centric Approach: We prioritize clear communication and collaboration, ensuring your needs and feedback are always at the forefront of our operations.

Let’s Bring Your Vision to Life

At TenX Manufacturing, we are passionate about turning your ideas into reality through our innovative injection molding solutions. Our experienced team is ready to work with you, providing the expertise and support you need to achieve your manufacturing goals.

Contact us today to discuss how we can elevate your projects with our comprehensive injection molding services. Together, we can create high-quality products that stand out in the marketplace and drive your success.

Request a Quote

TenX: The Best Manufacturing Company to Elevate Your Production

In the world of manufacturing, the best manufacturing company will become your partner who not only understands your needs but also consistently delivers top-quality solutions. Finding such a company can be a challenge. At TenX Manufacturing, we pride ourselves on our rich heritage and our unwavering commitment to excellence. With over four decades of experience, we have transformed from a small garage operation into a leading manufacturer with an impressive 80,000-square-foot facility equipped with cutting-edge technology.

A Legacy of Excellence

Founded in 1980 as Schmit Prototypes, our journey began with a focus on cast urethane parts and visual models. Through dedication and innovation, we quickly earned a reputation as the best manufacturing company known for our high level of quality in these specialized services. As our clients’ needs evolved, so did our capabilities. Today, we offer an extensive range of manufacturing solutions, including:

- Injection Molding (tooling, molded parts, assembly)

- CNC Machining

- Cast Urethane & Silicone Parts

- 3D Printing

This evolution has enabled us to not only provide low-volume and prototype work but also to transition seamlessly into full-scale production. Our rebranding to TenX Manufacturing reflects this commitment to going above and beyond for our customers.

What Does “TenX” Mean?

The name “TenX” encapsulates our mission and values:

- Ten: Representing our 10+ in-house capabilities, we strive to offer diverse manufacturing solutions tailored to your unique needs.

- X: Symbolizing our versatility, we provide both prototype and production volumes, ensuring that whatever your project demands, we are equipped to deliver.

Our customer-centric approach, combined with our state-of-the-art technology, empowers your business with manufacturing solutions designed to propel your success to new heights.

Commitment to Quality: ISO 9001:2015 Certified

Quality is at the heart of everything we do. Our ISO 9001:2015 certification is a testament to our dedication to maintaining the highest standards in manufacturing. This internationally recognized certification ensures that our processes consistently meet or exceed customer requirements and regulatory standards.

How does this benefit you?

- Enhanced Product Quality: Our ISO certification assures you that the products you receive will meet international quality standards, giving you confidence in your investment.

- Improved Customer Service: With a robust quality management system in place, we prioritize clear communication and prompt responses to your inquiries and concerns.

- On-time Delivery: Our streamlined production schedules and logistics optimization mean that you can count on us for timely deliveries, keeping your projects on track.

- Continual Improvement: We are committed to refining our processes based on your feedback, ensuring that we always strive for excellence in our products and services.

Work With The Best Manufacturing Company: Partner With TenX

As you consider your manufacturing needs, remember that TenX Manufacturing is more than just a supplier; we are your dedicated partner in innovation and quality. Our expansive capabilities, commitment to excellence, and customer-first approach make us the ideal choice for businesses looking to elevate their production experience.

Let us empower your success—contact us today to discuss how TenX Manufacturing can help you achieve your goals with precision and efficiency. Together, we can build a brighter future for your business.

Request a Quote

Ultimate Benefits of Plastic Injection Molding

Plastic injection molding stands out as a cornerstone of modern manufacturing. Its ability to produce complex, high-quality components quickly and at scale makes it indispensable for keeping up with the growing demand for efficient, versatile, and cost-effective manufacturing solutions.

This blog will guide you through the key benefits of plastic injection molding to help you see why it’s a preferred choice in sectors like medical tools, agriculture, aerospace, transportation, and electronics. By the end, you’ll clearly understand how this process can enhance your next manufacturing project.

What is Plastic Injection Molding?

Plastic injection molding is a manufacturing process where plastic material is melted and injected into a precisely crafted mold. Once the molten plastic fills the mold, it cools, solidifies, and takes on the desired shape with high precision.

Plastic injection molding is versatile enough to be used across various industries, and it can produce everything from intricate components to large, functional parts.

7 Benefits of Plastic Injection Molding

The many benefits of plastic injection molding make it a preferred manufacturing process for companies looking to increase operational efficiency and product quality:

1) Cost-Effectiveness

Plastic injection molding significantly reduces production costs, especially for large-volume orders. Additionally, the process results in extremely precise mold designs, reducing raw material waste. While the initial investment into this new process may seem high, the long-term savings in production efficiency and reduced material usage quickly offset the cost.

2) High Precision and Consistency

Another key benefit of plastic injection molding is its ability to deliver precision and consistency for complex designs. Once you create the mold, each product is virtually identical to the last. This level of precision and consistency is essential for highly regulated industries like aerospace, healthcare, and automotive.

3) Material Versatility

Plastic injection molding works with a wide range of plastics, including high-strength polymers and heat- or chemical-resistant options. The process also supports co-injection molding, in which you can combine multiple materials in a single component.

4) Design Flexibility

With plastic injection molding, you can create intricate shapes and fine details that might be challenging or impossible with other manufacturing methods. This flexibility opens the door for innovative designs so you can push boundaries and deliver cutting-edge solutions to your market.

5) Fast Production Cycle

components without compromising quality. Whether you need a small batch or a large-scale order, you can stay ahead of deadlines and keep your projects on track.

6) Enhanced Product Durability

When you use plastic injection molding, you can select materials with specific properties, such as resistance to wear, temperature fluctuations, or impact. You can trust that your components will perform under demanding conditions for the long term.

7) Environmental Sustainability

You can support environmental sustainability by incorporating recyclable materials into the plastic injection molding machine. Additionally, the process consumes less energy and creates less waste than traditional manufacturing methods.

Comparing Plastic Injection Molding to Other Methods

There are several benefits of plastic injection molding compared to other manufacturing methods like 3D printing, blow molding, and CNC machining. While 3D printing excels in prototyping, it struggles with high-volume production due to slower speeds and higher costs. Blow molding is practical for hollow parts but lacks the design flexibility and precision of injection molding. Although highly precise, CNC machining is typically slower and more costly for mass production.

Plastic injection molding stands out for its cost efficiency, speed, and scalability. It allows for rapid production of large quantities at a lower cost per unit. Maintaining high precision and consistency across large runs sets injection molding apart from other methods, offering the best balance of performance and economy.

Partner with TenX

Whether you’re working in medical tools, aerospace, or electronics, the benefits of plastic injection molding are clear – cost-effectiveness, high precision, design flexibility, fast production cycles, enhanced durability, and environmental sustainability.

Partner with TenX to make the most of these advantages and ensure your next manufacturing project is a success.

Request a Quote

Manufacturing Efficiency With CNC Technology

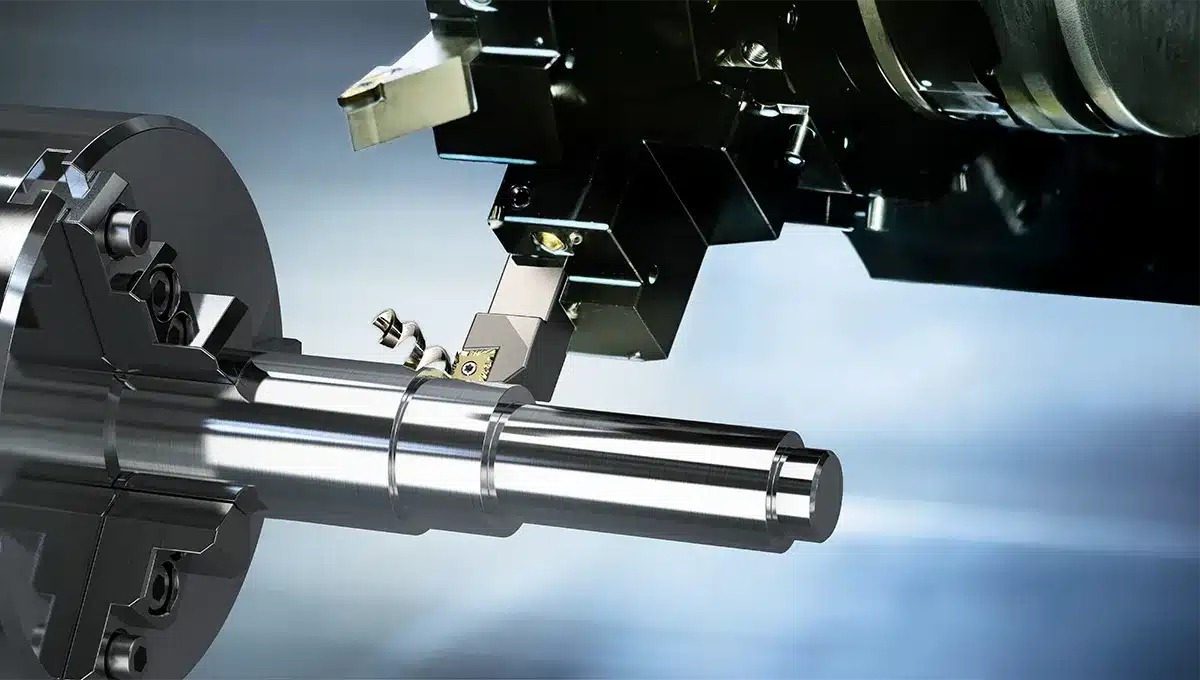

CNC (Computer Numerical Control) machining is a process where pre-programmed computer software dictates the movement of machinery and tools. This precise technology produces complex parts with incredible accuracy, consistency, and quality.

Automating the mass production of intricate designs with CNC has significantly increased manufacturing efficiency in the modern age. Today, the technology is indispensable for industries ranging from automotive to aerospace.

How CNC Improves Manufacturing Efficiency

Precision and Accuracy

CNC machines are renowned for their exceptional precision. Unlike manual machining, where human error can lead to inconsistencies, CNC machining makes each component to exact specifications. This level of accuracy improves the quality of the final product and minimizes the need for costly rework.

Automation and Consistency

By minimizing human involvement, CNC technology also reduces the potential for mistakes. The technology delivers uniform products and ensures they each meet the same high standards. This reliability enhances product quality and streamlines production, making it easier to achieve consistency across large production runs.

Faster Production Times

CNC machines offer significant speed advantages over traditional manufacturing methods – they can operate continuously, at high speeds, and with minimal downtime. The rapid production capability of CNC is essential in meeting tight deadlines and increasing overall manufacturing efficiency.

Versatility and Flexibility

One of the standout features of CNC machining is its ability to produce complex geometries that are difficult or impossible to replicate with other methods. The machines have versatile reprogramming capabilities, so you can quickly shift between different projects without extensive retooling.

Reduced Labor Costs

CNC automation inherently reduces the need for highly skilled manual labor. Instead of relying on traditional machinists to produce parts, CNC operators and programmers oversee the process. This shift can lead to significant savings when it comes to payroll.

Enhanced Material Utilization

CNC machining is designed to optimize material usage, therefore reducing waste. By precisely controlling the cutting and shaping processes, CNC machines minimize excess and maximize the yield from raw materials.

Integration with CAD/CAM Software

Integrating CNC machines with CAD and CAM software bridges the gap between design and manufacturing. By seamlessly translating complex blueprints into physical components with CNC, you can increase manufacturing efficiency and production flexibility.

Scalability

Unlike processes that require different setups or tools as production volumes increase, CNC machines can meet varying production needs without losing precision or efficiency. This capability makes CNC machining ideal for everything from prototyping to full-scale production, regardless of output count.

Commitment to Manufacturing Efficiency

CNC machining is superior for manufacturing due to its consistent, high-quality results with minimal waste and downtime. At Ten X, we are committed to delivering the highest levels of efficiency and quality in every project we undertake. Our state-of-the-art CNC machines and skilled team of experts allow us to meet the most challenging manufacturing demands with precision and speed. Request a quote for your next project.

Request a Quote

Benefits of Using a CNC Machine for Medical Parts Manufacturing

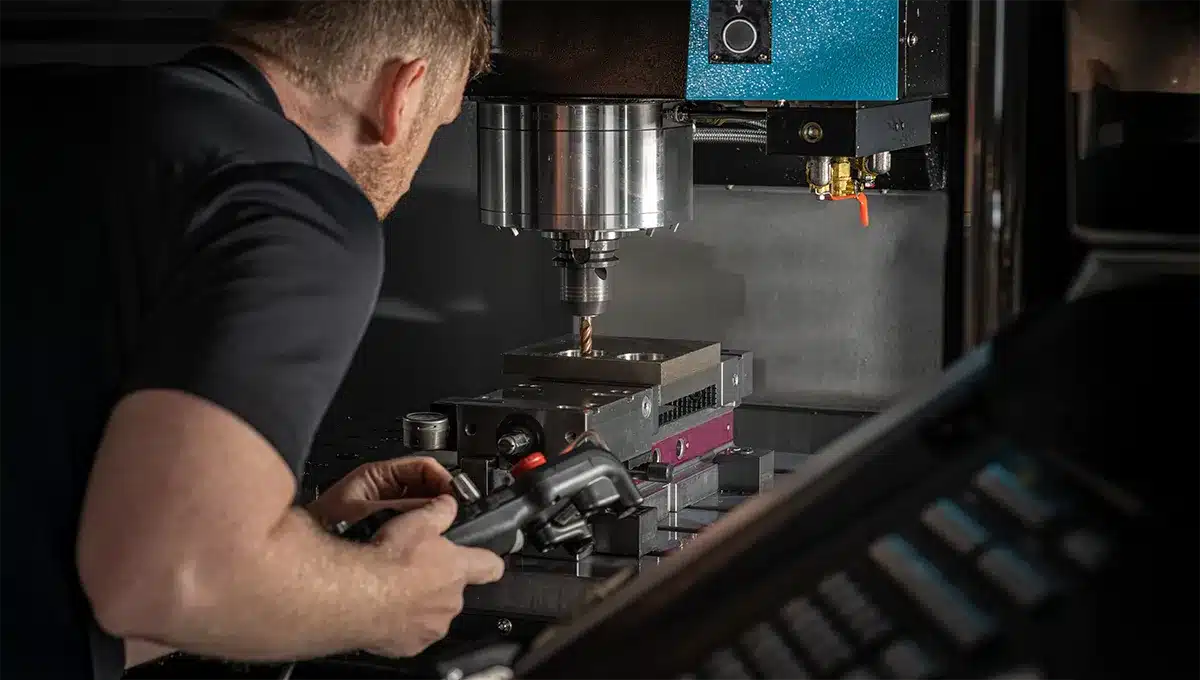

Precision and reliability are non-negotiable in medical parts manufacturing. As a company that sells medical instruments, you understand the critical need to produce tools that meet exact standards.

Computer numerical control (CNC) machining ensures medical parts are manufactured with the highest quality and precision, eliminating the potential for errors even at large scales. By working with a CNC medical parts manufacturing partner, you can mitigate risks, streamline production, and ultimately deliver superior products that uphold the integrity of your company.

Let’s explore how CNC machining can help you stay ahead in the competitive medical field.

What is CNC?

CNC, or computer numerical control, is a sophisticated manufacturing process that utilizes computerized controls and machinery to automate complex aspects of production. Pre-programmed software and code direct the cutting, drilling, milling, and shaping of materials, resulting in highly accurate and consistent outputs.

CNC machines can handle a wide range of materials, from metals and plastics to composites. They can also produce intricate designs with tight tolerances that would be challenging or impossible to achieve manually. Its versatility makes it a popular choice across many industries, including automotive, aerospace, and medical.

Advantages of using CNC for Medical Parts Manufacturing

CNC technology has become invaluable in medical parts manufacturing, minimizing human intervention and maximizing precision. Here are some advantages:

Unparalleled Accuracy

CNC machining allows for the production of medical parts with extremely tight tolerances, often down to micrometers. This level of precision is crucial for medical components, where even minor deviations can impact the functionality and safety of devices.

Production Consistency

CNC machining can consistently produce identical parts, regardless of the production scale. This repeatability is vital in the medical field, where components must adhere to strict regulatory standards, and any variation can lead to compliance issues or product recalls. CNC machines can replicate the same process multiple times, ensuring that each batch of parts meets the same high standards as the first.

Material Compatibility

CNC machines are compatible with various materials, including metals, plastics, ceramics, and composites. This versatility is essential in the medical industry, where different applications may require specific materials based on biocompatibility, strength, and durability requirements.

Safety & Compliance

The precision and consistency offered by CNC machines ensure that medical parts meet regulatory requirements, reducing the risk of non-compliance and potential liability issues. Additionally, CNC systems can maintain detailed records of production processes, aiding in traceability and quality assurance.

Cost-Effective High-Volume Production

CNC machining minimizes material waste, reduces labor costs due to automation, and lowers the likelihood of defects – all contributing to cost savings. Your company can produce higher-quality components at a lower price, which can be passed on as savings to healthcare providers and patients.

CNC machining offers a comprehensive solution for manufacturing medical parts. With high precision, consistency, and efficiency while accommodating complex designs and various materials, CNC can help you bring reliable and safe medical devices to the market.

Ten X CNC Medical Parts Manufacturing

Ten X is here to help you manufacture medical parts at the highest quality without mistakes. Request a quote when you’re ready to create safe and reliable products with CNC machining.

Request a Quote

Production Success: Design for Manufacturing and Assembly

The intricacies of production often make it difficult for companies to create a design for manufacturing and assembly (DFMA) that balances material selection, supply chain logistics, and product performance. As engineers and procurement professionals know, functionality, cost, and efficiency are critical aspects of bringing a product to market. This is where partnering with an original equipment manufacturer (OEM) can be invaluable.

OEMs have the expertise and resources to refine your design, ensuring it is manufacturable at scale while maintaining quality and performance. By leveraging their experience and specialized knowledge, you can streamline the production process, reduce costs, and mitigate risks.

This article explains what design for manufacturing is, its benefits, and how an OEM can help your company achieve its goals.

What is Design for Manufacturing and Assembly?

DFMA involves optimizing a product concept to reduce the number of parts, simplify assembly steps, and use standard components whenever possible. The goal is to minimize production costs and complexity while maintaining or improving product quality and performance.

By incorporating DFMA principles, you can create more cost-effective, reliable, and efficiently assembled products, ultimately leading to greater customer satisfaction and competitive advantage.

Benefits of Design for Manufacturing and Assembly

Here are some ways DFMA can improve your product development process:

Reduced Costs

OEMs utilize DFMA best practices to simplify the design and minimize the need for complex manufacturing processes. This can benefit your company by reducing material costs, labor expenses, and equipment costs. Expert OEMs achieve this cost reduction without compromising the product’s functionality, leading to a more economically viable product.

Improved Quality

By streamlining the design and focusing on ease of manufacturing and assembly, DFMA reduces the chances of defects and errors during production. Fewer parts mean fewer potential points of failure, and simplified assembly processes can reduce the likelihood of incorrect assembly. Producing a higher-quality product that consistently meets expectations can ultimately enhance your reputation and customer satisfaction, leading to increased business success.

Faster Time to Market

DFMA allows for more efficient manufacturing processes by addressing potential issues early in the design phase. By optimizing the design for easy manufacturing and assembly, you can significantly reduce the time required for production, testing, and adjustments. This accelerated timeline can give your company a competitive edge by allowing it to bring new products to market faster than its competitors.

Enhanced Design Flexibility

By considering manufacturing and assembly constraints from the beginning, OEMs can identify potential issues and adjust your design accordingly. This proactive approach prevents costly redesigns later in the development cycle and enables more seamless integration of new technologies or features.

A More Collaborative Approach

DFMA encourages closer collaboration between your company’s design engineers and your manufacturing partner. By working together from the start, these teams can identify potential manufacturing challenges and find solutions early. This collaboration fosters a more integrated approach to product development, resulting in more manufacturable and assembly-friendly designs.

DFMA provides a comprehensive framework for creating more efficient, cost-effective, and high-quality products. By integrating these principles into the design process, you can achieve significant advantages in all stages of development, production, and retail.

Ten X Design for Manufacturing and Assembly

Are you looking to bring a new product to market or improve your current process with a new manufacturing partner? The design for manufacturing and assembly team at Ten X specializes in injection molded parts, CNC machining, and urethane casting. We are here to help you refine your product’s design and handle all aspects of manufacturing for you.

Request a Quote

Understanding the Prototype to Production Process

Learn how to take your technical products from prototype to market with greater efficiency.

Knowing how your potential manufacturing partner will take your existing design from prototype to production is crucial before making a commitment. The journey involves several key stages designed to ensure quality, efficiency, and alignment with your requirements.

Initially, you’ll engage in detailed discussions to outline what you expect from your manufacturing team. This is followed by the prototyping phase, where your manufacturer will create and test mock-up versions of your product. Once you approve the prototype, pilot production will refine manufacturing methods and address any issues. After you and your manufacturer are satisfied with the pilot and overall process, you can launch into full-scale production with continuous quality control and communication.

Let’s explore each aspect of prototype to production in more detail so you know exactly what to look for when choosing a manufacturing partner.

Consultation

The process begins with in-depth discussions about your specifications, requirements, and expectations for the item(s) your manufacturer will produce. When working with a manufacturer whose responsibilities begin at the prototyping phase, you will need to bring several references material to this initial meeting, including:

- 2-D engineered drawings

- Blueprint of product/part

- Surface finish

- Critical dimensions

- 3-D digital renderings

- CAD file

Your manufacturing team will use these references to plan their approach for prototyping and ensure their methods align with your goals.

Prototyping

Prototypes are essentially a “first draft.” During this stage, your manufacturing team will test production processes and the product’s performance and aesthetics to identify and resolve any flaws or issues. You can bring other company stakeholders into this stage to gather feedback and make requested or required adjustments before progressing to the next phase of manufacturing.

Pilot Production

Pilot production is critical for ensuring your customers receive items that exceed expectations. Here, your manufacturer will assemble a small batch of your product(s) to guarantee they have resolved all concerns from the prototyping phase. If necessary, they will further refine their methods before full-scale production. This is the ideal time to test production workflow, identify any inefficiencies, and ensure quality meets your standards.

During this phase, your manufacturing partner will also work with you to develop detailed plans for mass production, including finalizing supply chain logistics, scheduling production runs, and establishing quality assurance protocols.

Full-Scale Production

Once all of your company’s stakeholders and your manufacturing team are satisfied with the pilot’s results, it’s time to launch full-scale production. Your manufacturer will implement the detailed production plan and deploy your rigorous quality assurance protocols in conjunction with their own. With the help of packaging and logistics teams, you’ll get your expertly engineered products delivered to customers intact and on time.

Take Your Product from Prototype to Production with Ten X

At Ten X, we have a team of highly skilled engineers, designers, and machine operators. When you need to take a technical product in the medical, agriculture, aerospace, transportation, or electronics industry from prototype to production, you can reduce costs and time-to-market by choosing a partner who handles everything under one roof.

Request a Quote

Benefits of One Stop Shop Manufacturing

As an engineer or procurement professional, you likely spend plenty of time and money coordinating multiple vendors for different stages of production. What if there was a more efficient way – a one-stop-shop manufacturing partner with in-house capabilities to take your product from prototype to production?

The Ten X approach speeds up timelines, cuts costs, and ensures better quality control. By having all services for manufacturing medical, agriculture, aerospace, transportation, and plastic electronic housing under one roof, you can focus more resources on improving your business.

Why One-Stop Shop Manufacturing?

Here are a few ways your company can benefit from one-stop shop manufacturing:

Better Communication

With all services under one roof, you eliminate the back-and-forth and potential miscommunications that often occur when dealing with multiple vendors. You’ll work with a single team that deeply understands your products, leading to smoother operations with fewer errors.

Faster Timelines

You can reduce downtime between stages by housing prototyping, production, and finishing under one roof. Additionally, you don’t have to waste time dealing with external coordination whenever you need to adjust products – your one-stop team will implement changes immediately. With this approach, you will significantly accelerate the overall production timeline and bring your product to market faster.

Lower Costs

Using a one-stop shop manufacturer avoids extra costs and logistical complexities that come with juggling various suppliers. Additionally, bulk pricing and bundled services from a single provider can mean significant financial savings for your company and a more cost-effective production process.

Improved Quality Control

When the same team oversees every stage of manufacturing your products, you can rely on a thorough understanding of specifications and quality expectations from design to post-processing. Your critical devices will have more consistency across the board because they are all made in the same facility.

Simplified Project Management

Coordinating multiple suppliers involves extensive scheduling, monitoring, and communication, which can be time-consuming and prone to errors. You can simplify all aspects of project management by using one facility that provides a single project timeline and unified progress reports.

Enhanced Innovation

A one-stop shop can provide integrated solutions and creative approaches that may not be possible with a fragmented production pipeline. When the entire manufacturing team works together from start to finish, there is a continuous exchange of ideas and feedback. Rest assured that your manufacturer is working behind the scenes to innovate and optimize production – your company will benefit from better products and more successful projects.

Ten X Is Your One-Stop Shop Manufacturing Partner

Save your company resources and give your customers more reliable products by switching to Ten X – your one-stop shop manufacturing partner for all medical, agriculture, aerospace, transportation, and plastic electronic housing needs.

Request a Quote

Working Direct with a Manufacturer vs. Service Bureau

In the dynamic world of manufacturing, businesses seeking services like Injection Molding, CNC Machining, Urethane Casting, and 3D Printing often face a common challenge – choosing between working directly with a manufacturer or opting for a service bureau. At TenX Manufacturing, we take pride in offering a unique advantage by providing all our services in-house. In this blog post, we will explore the benefits of working directly with a manufacturer like TenX, as opposed to navigating the maze of outsourcing and hidden charges associated with service bureaus.

- End-to-End Control: One of the key advantages of choosing TenX Manufacturing is the assurance of end-to-end control over the entire manufacturing process. From concept to completion, we have a dedicated team of experts handling Injection Molding, CNC Machining, Urethane Casting, and 3D Printing under one roof. This not only ensures a seamless workflow but also guarantees that the final product meets the highest quality standards.

- Single Point of Contact: When you partner with TenX, you gain the convenience of having a single point of contact throughout your project. Unlike service bureaus that may involve multiple intermediaries, TenX streamlines communication, reducing the likelihood of misunderstandings or delays. This direct line to the manufacturer allows for clearer communication, faster issue resolution, and a more personalized customer experience.

- Cost Efficiency: Outsourcing to service bureaus often comes with hidden fees and upcharges, leading to unexpected costs for the end customer. At TenX Manufacturing, we eliminate these uncertainties by providing transparent and competitive pricing. With all services in-house, we maintain control over costs and can offer a more cost-effective solution without compromising on quality.

- Quick Turnaround Times: In the fast-paced world of manufacturing, time is of the essence. Working directly with TenX allows for quicker decision-making and a more efficient production process. Our streamlined workflow ensures faster turnaround times, enabling you to meet tight deadlines and respond promptly to market demands.

- Customization and Flexibility: TenX Manufacturing understands that every project is unique. By working directly with us, you have the flexibility to customize your manufacturing process according to your specific requirements. Whether it’s modifying designs, adjusting production volumes, or incorporating special features, our in-house capabilities provide the flexibility needed to bring your vision to life.

In a market flooded with options, TenX Manufacturing stands out by offering a comprehensive suite of services under one roof. By choosing to work directly with us, you not only benefit from end-to-end control, cost efficiency, and quick turnaround times but also gain a valuable partner committed to your success. Say goodbye to the uncertainties of outsourcing and embrace the TenX advantage for a manufacturing experience that prioritizes precision, transparency, and customer satisfaction.

Injection Molding, Backed by ISO9001:2015 Certification

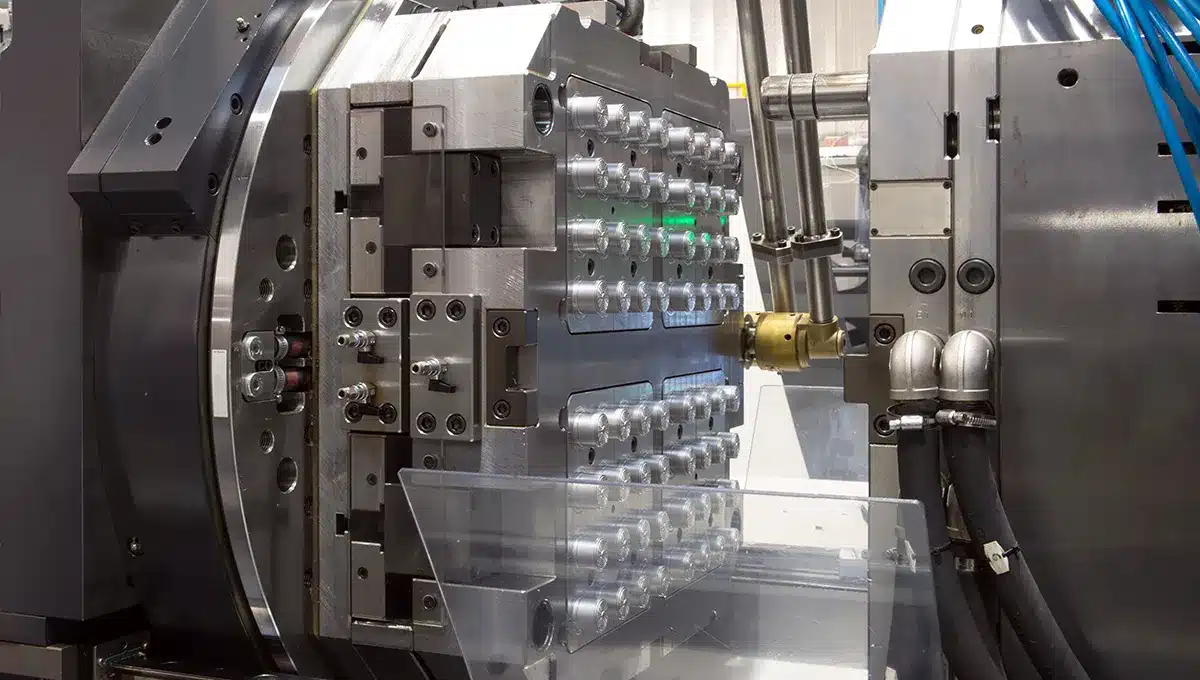

In the dynamic world of manufacturing, efficiency is the key to success. TenX Manufacturing takes pride in offering a unique and comprehensive solution in the realm of injection molding. Unlike many competitors who specialize in either injection mold tooling or molded parts, TenX stands out by providing both services under one roof. This integrated approach not only streamlines the production process but also offers significant benefits to customers. Furthermore, TenX Manufacturing is proud to be ISO9001:2015 certified, underscoring our commitment to quality and customer satisfaction.

- Time Savings Through Vertical Integration: One of the standout features of TenX Manufacturing is the seamless integration of injection mold tooling and molded part production within a single facility. This eliminates the need for customers to ship tools or molded part samples back and forth between separate suppliers. This reduction in logistical complexities translates into substantial time savings, expediting the entire production timeline.

- Collaborative Expertise for Optimal Results: TenX’s competitive edge lies in fostering collaboration between highly skilled toolmakers and process engineers who work closely together throughout the entire manufacturing process. From the initial stages of Design for Manufacturability (DFM) to tool design and build, the partnership between these two critical entities ensures a holistic and cohesive approach. This collaboration guarantees that the final molded parts meet the highest standards of quality and precision.

- Collective Knowledge Advantage: Having both toolmakers and process engineers under one roof provides TenX Manufacturing with a unique collective knowledge advantage. The synergy between these teams allows for real-time problem-solving, continuous improvement, and efficient decision-making. This not only enhances the overall quality of the injection molding process but also positions TenX as a reliable partner capable of adapting to evolving customer needs.

- Seamless Transition from Prototyping to Production: TenX’s integrated approach enables a smooth transition from prototyping to full-scale production. With the entire process taking place within the same facility, adjustments and improvements identified during the initial prototyping phase can be seamlessly incorporated into the production process, ensuring a more efficient and cost-effective manufacturing journey.

- ISO9001:2015 Certification – Ensuring Quality and Customer Satisfaction: TenX Manufacturing’s commitment to excellence is further demonstrated by our ISO9001:2015 certification. This internationally recognized quality management standard ensures that our processes are systematically monitored and continuously improved. By adhering to ISO9001:2015 standards, we guarantee a high level of quality control throughout the injection molding process, resulting in products that consistently meet or exceed customer expectations.

- Customer-Centric Approach: By offering a comprehensive solution, TenX Manufacturing demonstrates a customer-centric approach. The elimination of the need to coordinate between multiple suppliers not only simplifies the customer experience but also reduces the likelihood of miscommunications and delays, contributing to overall customer satisfaction.

In a competitive market where time and precision are of the essence, TenX Manufacturing’s all-in-one solution for injection molding, backed by ISO9001:2015 certification, sets it apart as a reliable and efficient partner for businesses seeking a streamlined manufacturing process. With an integrated team of experts and a commitment to quality and customer satisfaction, TenX is poised to be the go-to choice for injection molding services.