When it comes to injection molding solutions, finding a reliable partner who can handle every aspect of the process is crucial to your project’s success. At TenX Manufacturing, we stand out in the industry by offering a comprehensive suite of injection molding solutions—DFM (Design for Manufacturing), injection mold tooling, molded parts, and assembly—all under one roof. This unique capability allows us to deliver exceptional results efficiently and effectively.

Comprehensive Injection Molding Solutions

At TenX Manufacturing, we understand that the success of any injection molding project starts with meticulous planning and design. Our DFM services ensure that your designs are optimized for manufacturability, reducing production costs and time. We work closely with you to assess every aspect of your project, identifying potential challenges and opportunities to enhance performance.

Here’s how we streamline the injection molding process:

- DFM (Design for Manufacturing): Our expert team collaborates with you from the very beginning to refine your designs, ensuring they are feasible for production. By identifying potential issues early on, we can prevent costly revisions later in the process.

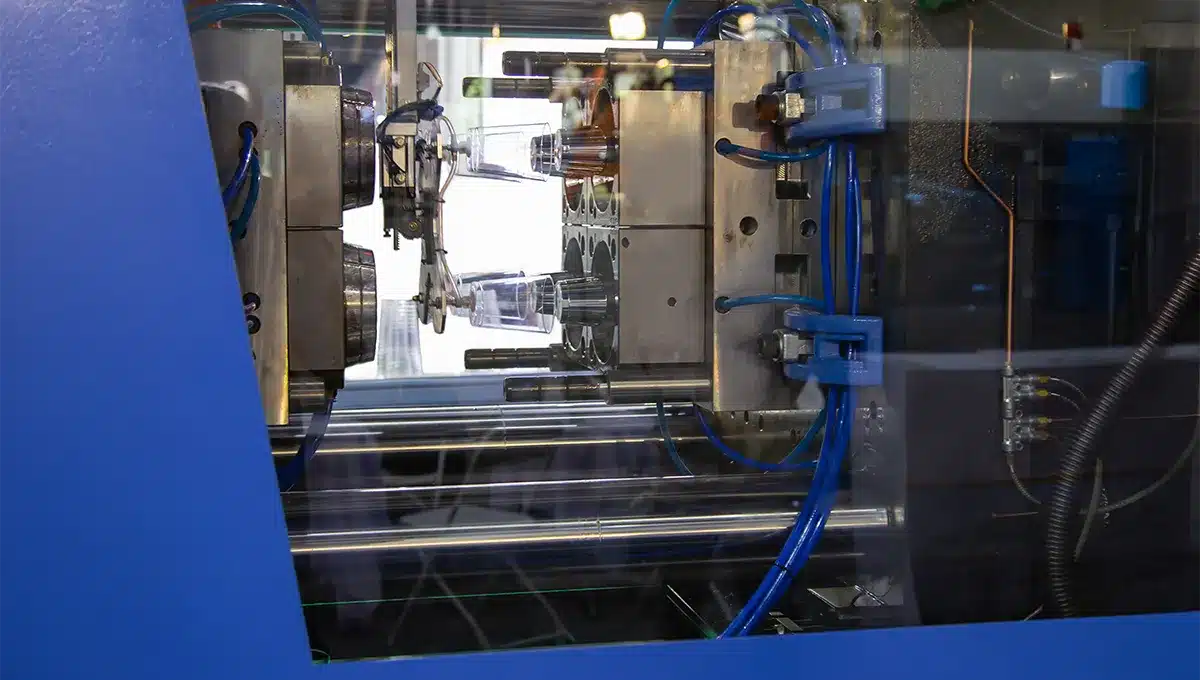

- Injection Mold Tooling: With our state-of-the-art facility and advanced equipment, we create high-quality molds that meet your specific requirements. Our in-house tooling capabilities mean faster turnaround times and improved quality control, as we can address any adjustments immediately.

- Molded Parts Production: Whether you need prototypes, bridge solutions, or full-scale production, we have the expertise and technology to deliver. Our experienced team ensures that every molded part meets rigorous quality standards, providing you with confidence in your final product.

- Assembly Services: To further simplify your manufacturing process, we offer comprehensive assembly services. Our team can handle the assembly of components, allowing you to receive fully finished products ready for market. This streamlined approach reduces the need for multiple suppliers and enhances communication throughout the project.

Flexibility to Meet Your Needs

At TenX Manufacturing, we recognize that each project is unique. That’s why we cater to a variety of production volumes—be it prototype, bridge, or full production runs. Our agility allows us to adapt to your specific requirements, ensuring that we deliver solutions tailored to your needs.

Why Choose TenX Manufacturing?

Choosing TenX Manufacturing means partnering with a company committed to excellence. Here are a few reasons why we stand out in the injection molding landscape:

- All-in-One Solution: With DFM, tooling, molded parts, and assembly services available in-house, we provide a seamless experience from concept to completion.

- Quality Assurance: Our ISO 9001:2015 certification underscores our commitment to quality, ensuring that every product meets stringent international standards.

- On-Time Delivery: Our optimized processes enable us to deliver your orders promptly, keeping your projects on schedule.

- Customer-Centric Approach: We prioritize clear communication and collaboration, ensuring your needs and feedback are always at the forefront of our operations.